Page 1 of 1

new wheels

Posted:

Wed Mar 31, 2010 9:54 amby zipperd50

i was thinking about putting bigger wheels on my truck other then the 14s that are on it now and i was wondering what would be the biggest i could put on there without doing anything to the suspension or the hub or wheel to make them fit? i came across a set of 17s for free from a ford f150 that were the same 6 lug pattern the only problem i had was the tires were too fat and the hub didnt quite fit as tight as i wanted it to so i got rid of them. also my suspension sucks really bad and makes the truck look lower then it should which im hoping once i get new shocks it will help.

Re: new wheels

Posted:

Wed Mar 31, 2010 12:40 pmby pennyman1

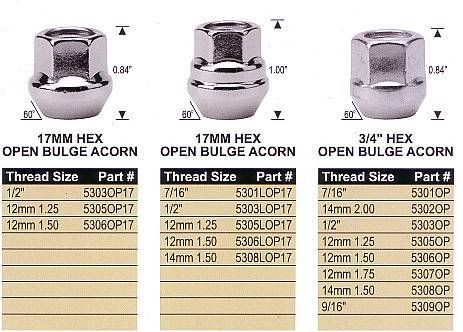

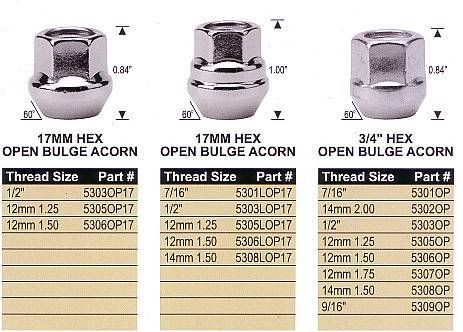

These truck use a 6x5.5" lug pattern that is a large center hole. It is the same as pre87 GM full size pickups and older toyota 4wd trucks. The ford wheells are 6x135mm, and are a hubcentric design; 6x5.5 is 6x139.7. Many people on here get the 88 and up GM truck wheels and have the centers bored out to fit or grind off the tabs on the front hubs and turn down the rear axle hubs. Those wheels also require a "bulged" lugnut to properly center on the axle. Hope this helps.

Re: new wheels

Posted:

Wed Mar 31, 2010 10:16 pmby Bernie Lowmax

I agree with Pennyman, make sure you use "bulged" or also known as "acorn" lug nuts to center the wheel out. If not you will have a wicked vibration, take it from someone who learned the hard way! And PS, i`m largely against grinding out the centers of the wheels. Ive seen them crack. Grind the tabs off the front hubs, and get the rear axles "turned down" by a drive shaft shop or machinist. Much safer but to each his own. Hope that helps

Re: new wheels

Posted:

Wed Apr 14, 2010 6:38 amby aztlan.d50

hey man i am in the same situation , i just buy some cady wheels and i do not wat to do bored them or save the front disc but i do not now how to turn down the axles any aideas .....instructions will help alot

Re: new wheels

Posted:

Wed Apr 14, 2010 8:23 amby DroppedMitsu

Best way would be to smooth out the tabs on a lathe, but since most ppl don't have access or want to spend money on it you can take something like an angle grinder and cut/grind down the tabs flush with the rest of the hub surface